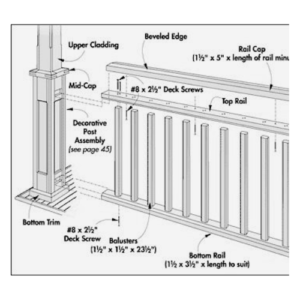

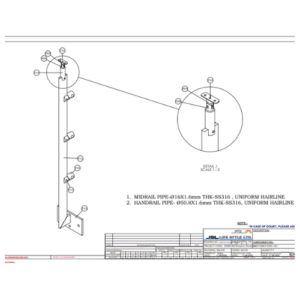

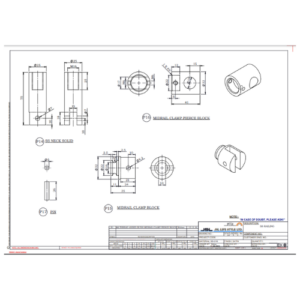

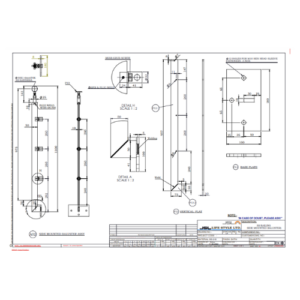

Preparation of shop drawings/3D models / isometric views with detail spare parts drawing.

Cutting of materials on

- Automatic circular saw /Bandsaw with precision of 0.05mm

- Notching & grinding of materials

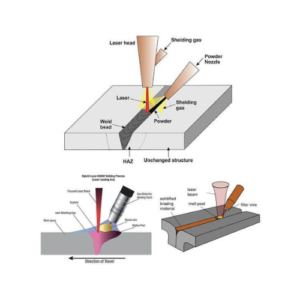

Welding process of stainless steel components:

- TIG

- TIG Auto feed M/C

- Laser Welding (latest addition in technology)

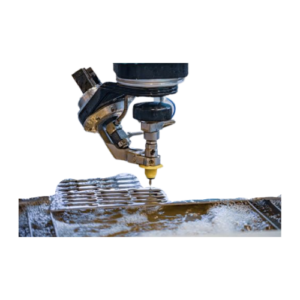

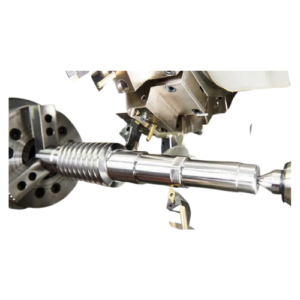

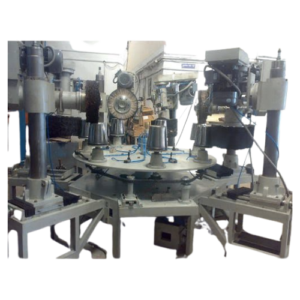

All accessories of railing produced through:

- Laser cutting

- Waterjet cutting

- CNC turning center

- CNC vertical milling center

- CNC drilling and tapping center

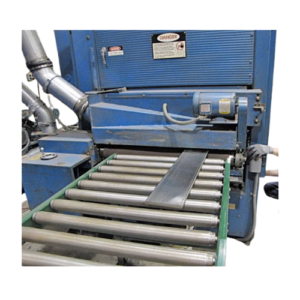

Buffing and Grinding through

- Automatic pipe polishing M/C

- Automatic Flat polishing M/C

- Automatic surface finishing M/C

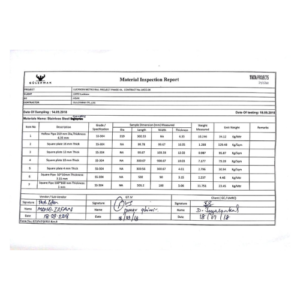

Assembly and quality inspection

- Packing with laser marking of authenticity

- Deconnection with related MTCs/Batch Certificates

Installation through our skilled installers trained by JSSL/Dorma.